Fiber Laser Cutting Machine

Advantages of Fiber laser cutting Machine

There are many advantages of a Fiber laser cutting machine this machine becoming a goldmine for many industries and may you know many application fields using this Fiber laser cutting technology to boost their productivity and grow their business rapidly. There are five main advantages of Fiber laser cutting machines.

Boost in Cutting Speed : Fiber laser cutting machine provide a good cutting speed that means it has the ability to finish work quickly in a short time and gives a better finishing with best quality. When cutting a straight line of 1mm in thickness, a fiber based laser can cut more times faster than that of a traditional laser.

Superior Performance : You will also find that fiber lasers provide better performance than many of their counterparts. Fibers provide a high level of laser beam quality that can be highly focused to achieve extremely accurate levels of accuracy as well as increased power density.

Cutting Reflective Material : One of the main problems while using a traditional laser is with respect to the reflective material. There is a chance that a laser reflector may bounce off the material, which in turn will damage the material. Due to this, traditional lasers are not often used when cutting aluminium, brass and copper. However with fiber optic lasers, this reflective material problem is no longer an issue, which in turn allows cutting these materials

No Moving Parts : One of the main problems while using a traditional laser is with respect to the reflective material. There is a chance that a laser reflector may bounce off the material, which in turn will damage the material. Due to this, traditional lasers are not often used when cutting aluminium, brass and copper. However with fiber optic lasers, this reflective material problem is no longer an issue, which in turn allows cutting these materials

Higher Electrical Efficiency : The Fiber optic configuration will not only save power each time it is used, but it also helps to extend the life expectancy of the hardware due to lower energy requirements. No task is too complicated for a laser cutter. High powered lasers can be used on a very narrow section of material and cause very little warping or distortion in this area.

Less Expensive: Probably the most valuable benefit of fiber laser cutting is the price. The cost overhead for this technique represents an initial savings and a large savings over the lifetime of the laser. For starters, it does not require expensive optical mirrors, as is the case with other laser technology. Additionally, the focusing lens is not exposed, but rather sealed within the cutting head. Because of this, concentrating lenses, when properly maintained, require damage rather than damage and frequent replacement during the lifetime of fiber optics, which occurs with laser applications.

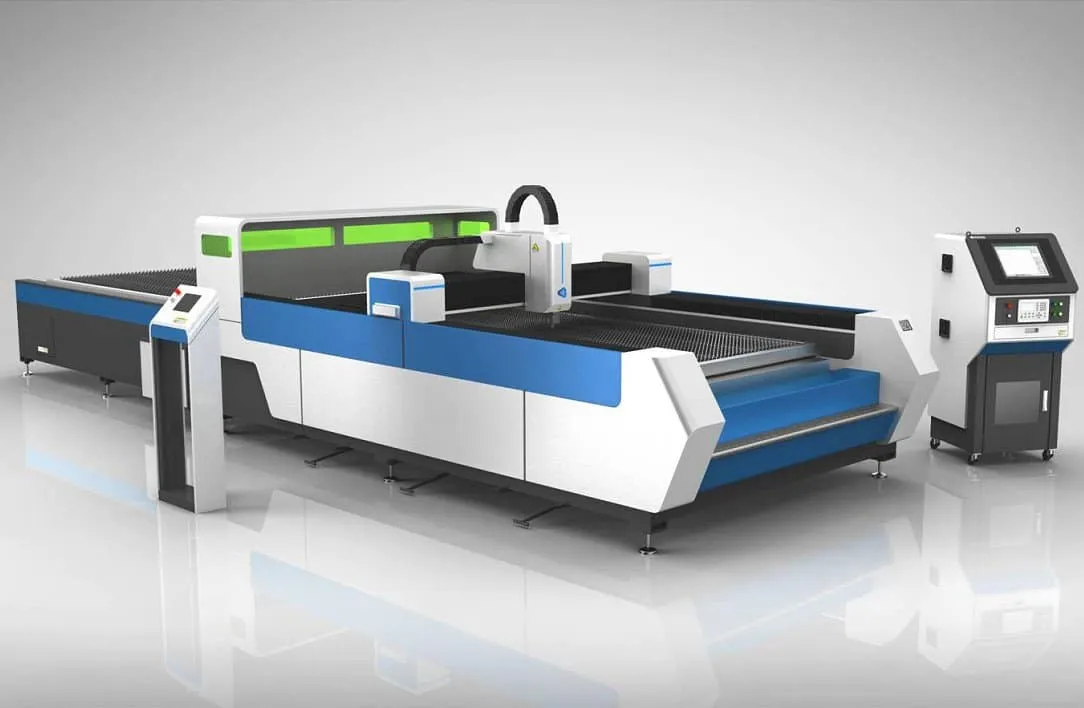

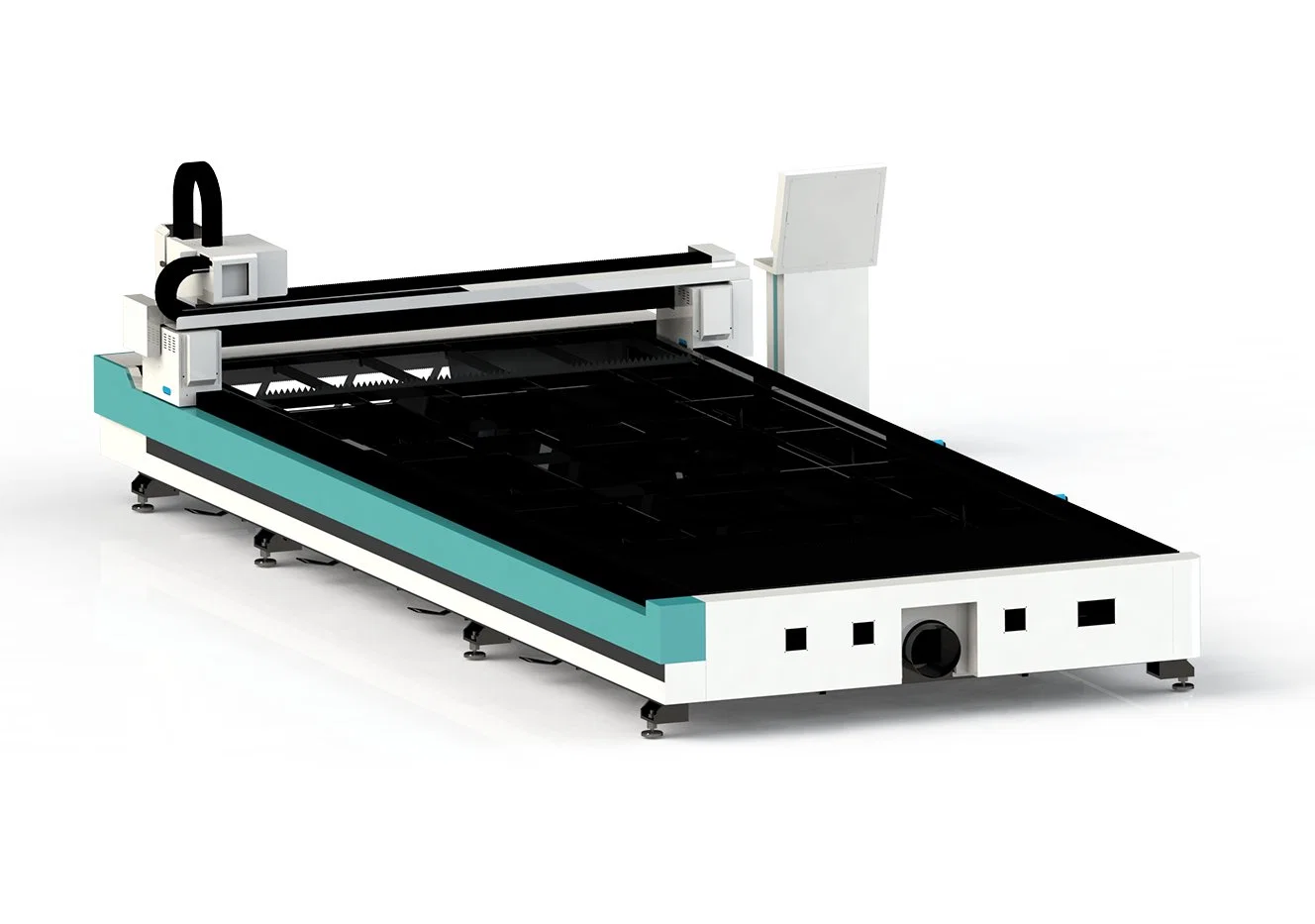

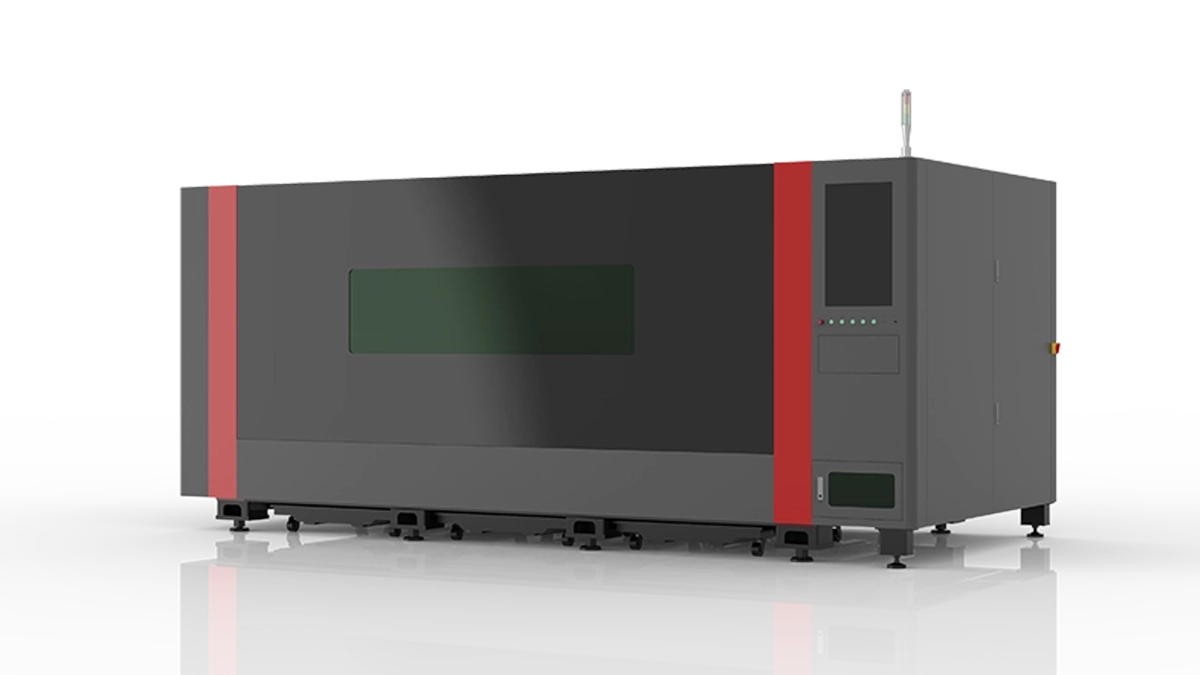

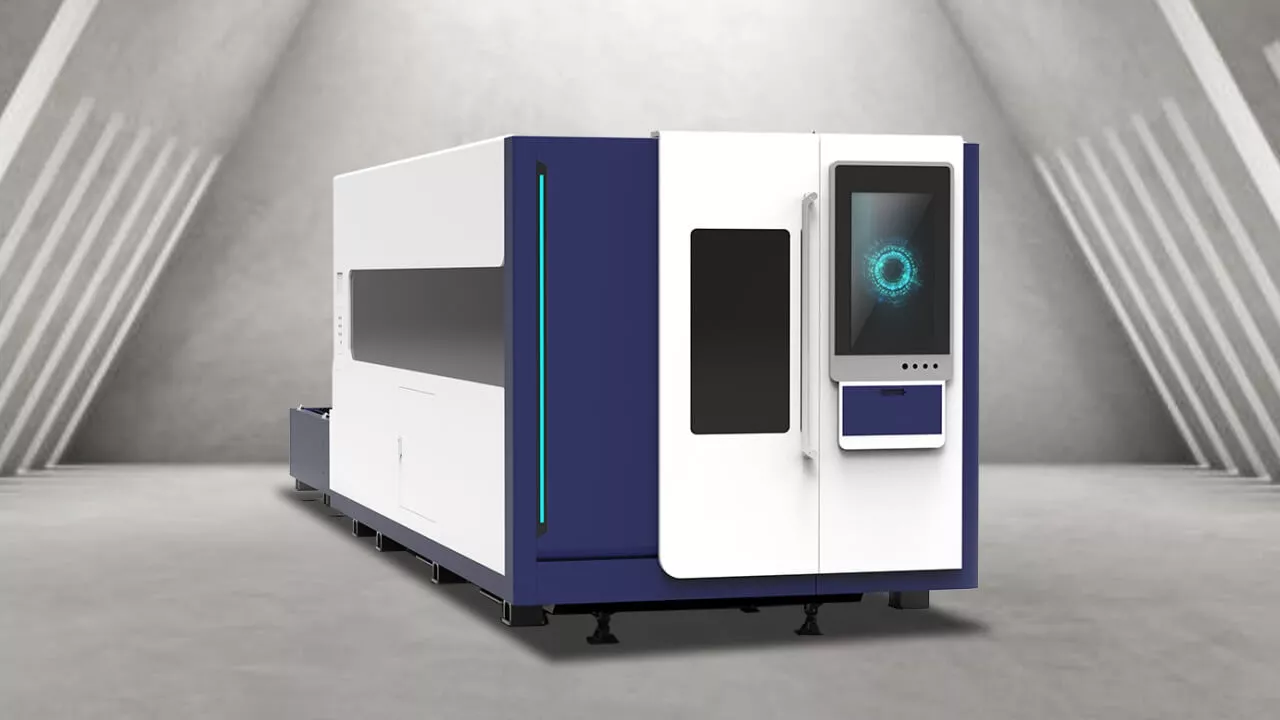

Some Design of Laser Cutting